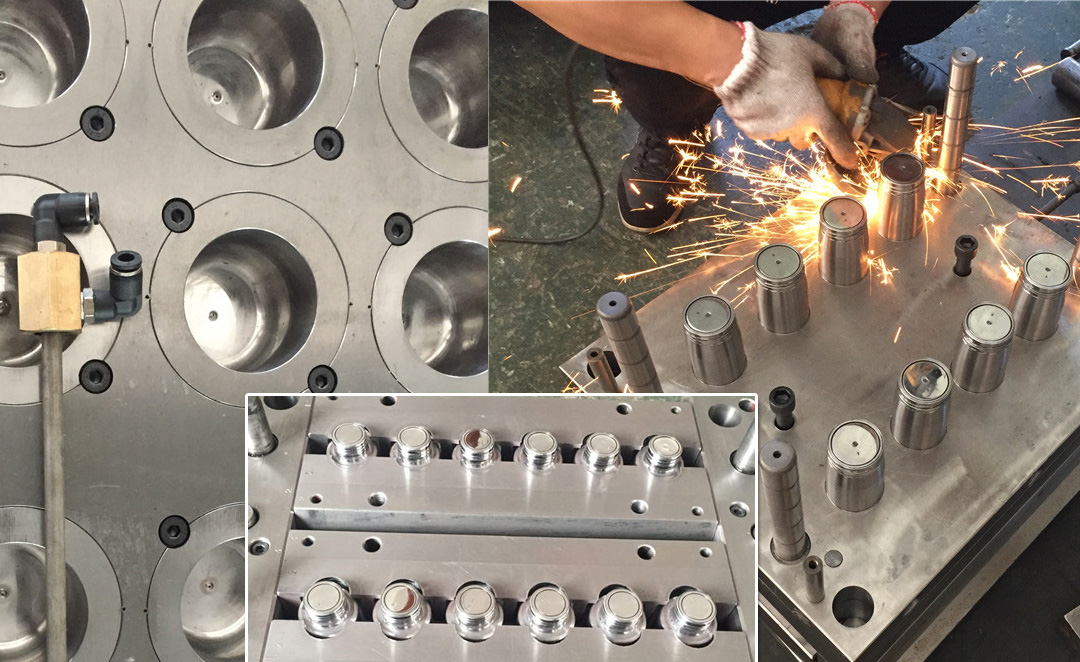

Custom Rubber Mould Manufacturer Injection Mould of Custom Rubber Part

07. Polymer Report History of Rubber The story of Charles Goodyear and vulcanization You can not speak about the history of rubber without mentioning Charles Goodyear. His name graces the tires under millions of automobiles and is credited with inventing the process for the modern form of rubber: Vulcanization.

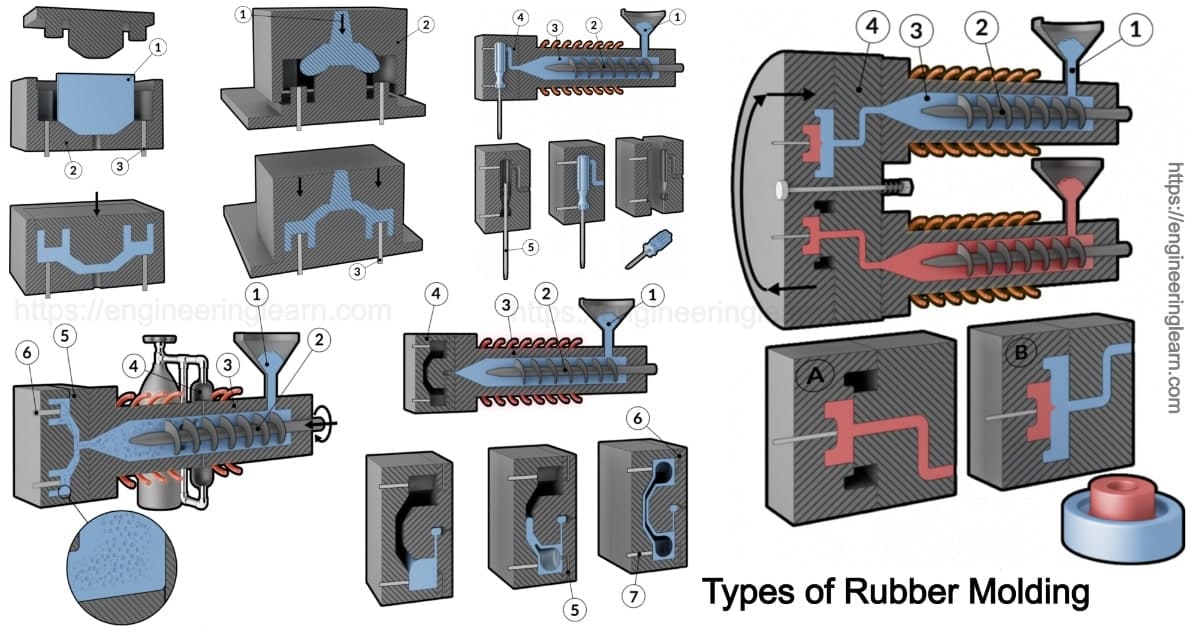

Types of Rubber Molding Engineering Learn

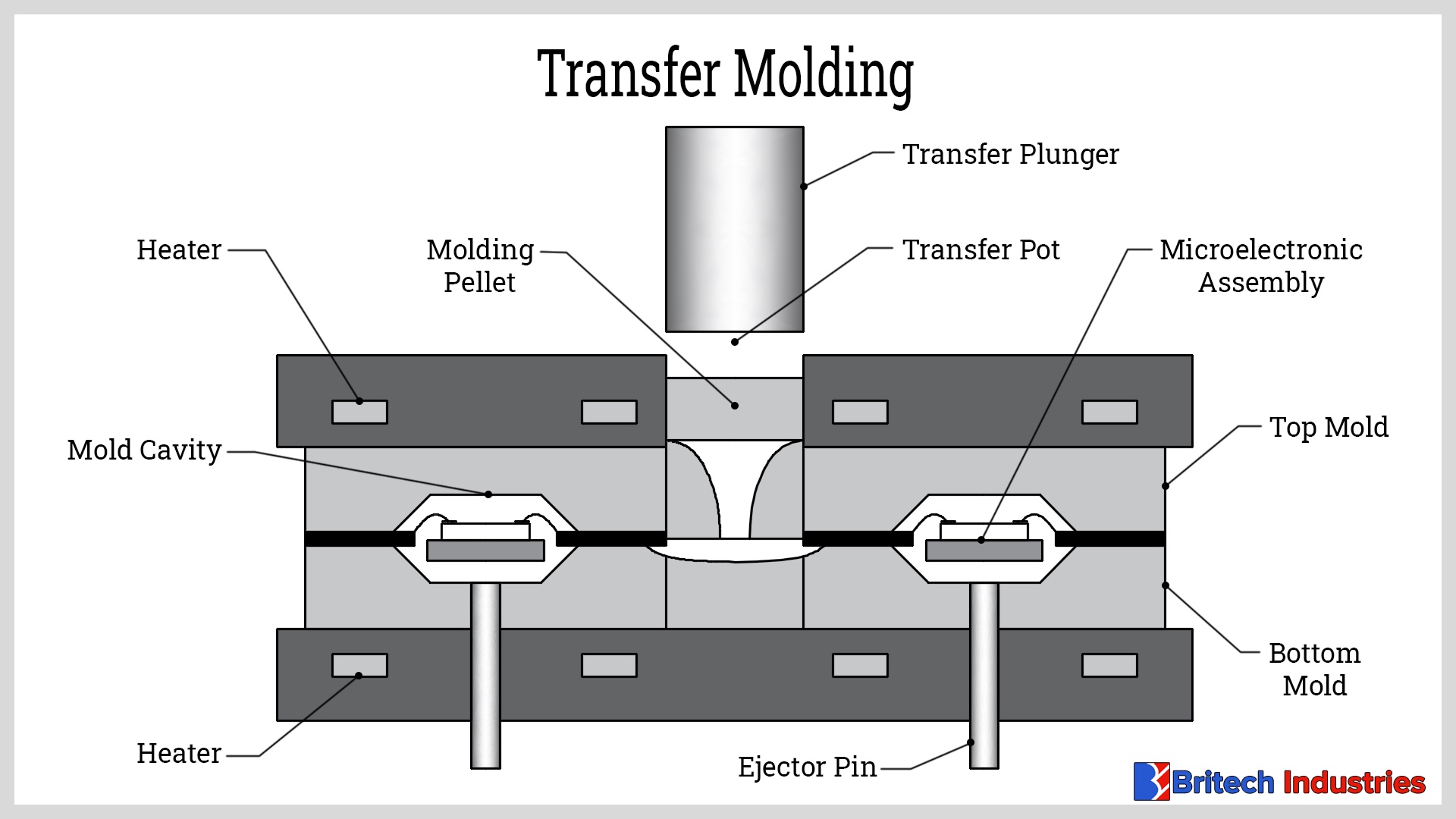

Rubber transfer molding is an ideal process for molding parts that require multiple cavities, intricate parts that require a closed mold, bonding rubber to metal parts and if the geometry of the part might cause mold cavities to trap air. Processes

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

In our opinion, the ideal location to site your MVHR unit in a home is in a utility/plant room on the north side of the building close to an external wall. The reason we prefer it on the north elevation is to improve the efficiency of the automatic summer bypass function that all our MVHR units have built in.

Rubber Transfer Molding Custom Rubber Transfer Molding Experts

Rubber Molds & Products Manufacturer serving Rubber Mold Design offers rubber mold design for quality rubber molds to make rubber molded products around Rubber Mold Design. Call 1 (647) 294-5240 for quote. Custom Rubber Molded Products For Automobile, Aviation, Mining,.

Rubber Molding Rubber Molded Parts Britech Industries

Updated: July 19, 2022 Rubber products are ubiquitous in nearly every industry nowadays. They play a vital role in functions like sealing, abrasiveness, insulation, etc. As a result, they are critical in upholding high industry standards and development in today's fast-paced world.

Rubber Mold Design Services, Rubber Moulding Services, रबड़ मोल्डिंग

This comprehensive design tool details rubber and plastic design issues including a materials overview and prototype mold design considerations. Designing Rubber Components Overview Working Together Engineering Design Cost Effective Custom-Molded Seals Avoiding Rubber Component Design Problems Properties in Balance Selecting an Elastomeric Material

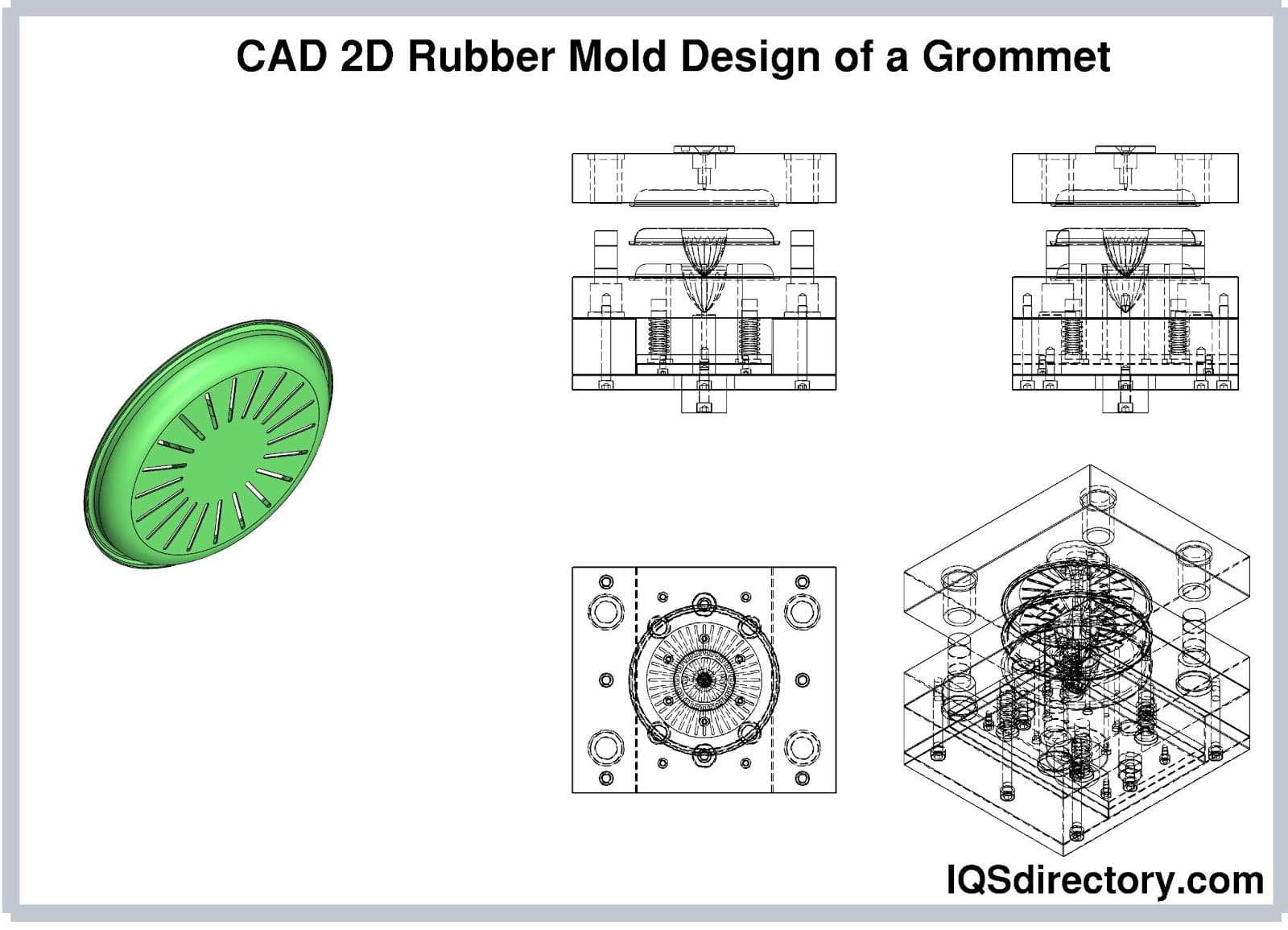

Rubber Molding What Is It? How Does It Work? Types Of

At Martin's Rubber, we have a dedicated tooling department that allows us to be agile and responsive to your prototyping needs. We can design an effective mould tool for your specified rubber mould design using high-tech CAD and CAM software. We will adapt your 2D or 3D drawings and liaise closely with you until you are satisfied with the.

Rubber & Silicone Molding Manufacture Sanhao Custom Rubber

«The Design Factory is a place where new ideas are transformed into tangible products with high added value,» says Guntis Kuļikovskis, Head of Riga Technical University Design Factory (RTU DF). He explains that activities at the Design Factory can happen at various levels. The first steps are usually taken in The Lab, an open laboratory located in the basement of the RTU Faculty of.

Liquid Silicone Rubber Mold Design with Cold Runner

Rubber moulding is a flexible production procedure that uses specialized moulding to shape rubber products into numerous kinds. Rubber moulding supplies numerous advantages, including style versatility, product flexibility, cost-effectiveness, and improved product performance.

THE CUSTOM RUBBER MOLDING Professional Tooling Mold Maker, Rapid

The Engineer's 7-minute Guide to Rubber Molded Parts is just as it sounds, a quick-reference guide to help you determine if exploring a rubber part is right for your application. Designing new products or parts around existing components can be costly and time-consuming.

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

Rubber Molding manufacturing is facilitated by either extruding, pressing or pouring a liquid into a mold. Most rubber products made from vulcanized rubber with sulfur at high temperature during the molding process or after extruding.

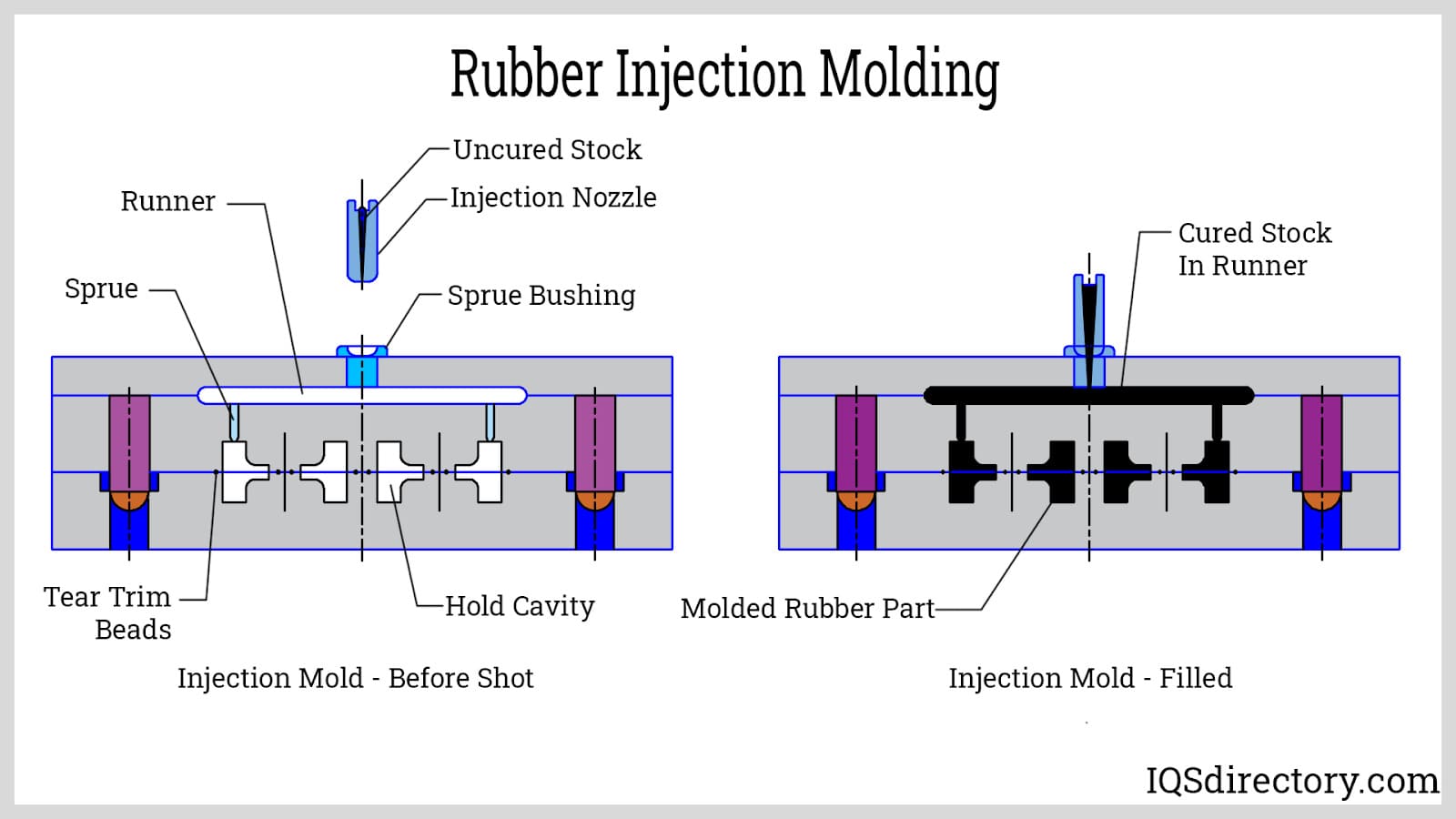

Rubber Injection Molding Rubbers, Processes, Applications, and Advantages

Our company offers services for the production of plastic products. From product design and mold making to mass production in batches. We manufacture injection molding products using such materials as polyethylene (PE, low density polymer, high density polymer), polypropylene (PP, PP-R, PPH, PPC, PP + Glass Fiber), polystyrene (PS.

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

Custom Molded Rubber Parts RESPONSIVENESS ~ FROM DESIGN TO DELIVERY™ We are committed to delivering not just quality molded rubber components on time, but also delivering the best customer experience throughout the entire process, for the life of the relationship. Services Custom Rubber Corp. focuses on a core competency of molding rubber parts.

Custom Made Rubber Mold Mould

Rubber molding is a process that can be used to create parts with a wide variety of shapes, sizes, and designs. A rubber mold is an integral part of the rubber production process because it allows the component, part, configuration, and design of a rubber product to be precisely tuned to match the requirements of an application.

Explanation of detailed knowledge points of rubber mold design in

Rubber molding is a manufacturing process that turns uncured rubber and other elastomeric materials into usable parts and products. It involves placing, pressing, or injecting the material into the cavity of a metal mold. Then, pressure and heat are applied, which initiates a chemical reaction—i.e., curing or vulcanization—within the material.

Rubber Moulding Process Comparisons DP Seals

Molding of Rubber and Design of Rubber Molds Learn the fundamentals of molding rubber mechanical goods and designing their rubber molds with no reference to the molding of tires. Review applicable molding methods with emphasis on compression, transfer and injection processes.